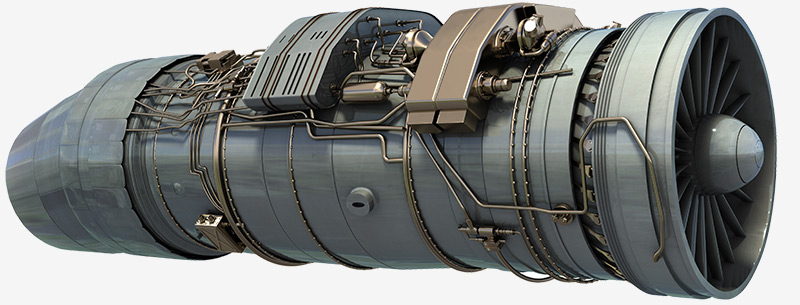

Taking Our Quality Management System To A Higher Altitude

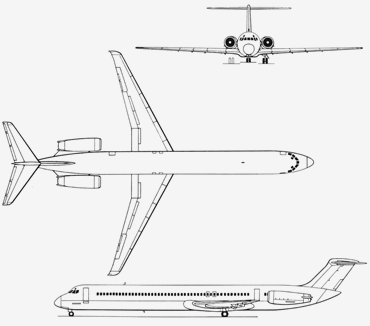

Our quality system is fully compliant with the latest issue of ISO 9001:2015 and EN 9120:2016 in the scope of distribution and trading of new and repaired aeronautical products, parts and appliances.